SHREE UDYOG

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SHREE UDYOG

Hopper Autoloader

The Hopper Auto-loader ensures that the hopper is always full. The ladder stops loading material once the hopper is full and automatically restarts the loading as soon as the material level inside the hopper falls.

The turbine blower exhausts air from the receiver creating a vacuum. Due to the vacuum, material from the bin rises via the flexible pipe connecting the receiver to the material suction probe (the probe remains partly submerged in the bin containing resins/ materials). An efficient filter between, filters the air to remove 'fines' and dust of the resin. Timer on panel controls loading time.

The material is unloaded from the receiver into the hopper via a flapper gate, which opens under the weight of the material. Once the material is unloaded into the hopper and receiver is empty, the flapper gate closes and the cycle of suction of the material from the bin restarts a gain with 3-5 seconds delay.

Pneumatic Conveying System

¬Shree Udyog specialises in manufacturing different types of pneumatic conveying systems. Years of experience have helped us pioneer the design for various material conveying systems. Our Pneumatic conveying systems provide high efficiency and have been tried and tested in various industries for their better performance. We only make use of high-grade raw material to manufacture our products. We make use of different materials depending upon the requirement of material to be conveyed.

- Material Conveyed:

- Food Grains

- Pulverized material

- Plastic granules

- Polymer chips

- Plastic grinding

- Material Conveying

- Plastic Chippings

- Paint Powder

Air Knife

|

Axial Flow Fans

We offer Axial Flow Fans that displace very large quantity of air at comparatively low pressure. These fans are ideal for ventilation and air conditioning requirement. Our axial flow fans are particularly useful for handling hot air, moist air, gas fumes. Tube axial fans / Axial Flow Fans are particularly useful for handling hot, moist air or gas and fumes and providing fresh air.

Industries catered:

Our Axial Flow Fans are particularly useful for the following Industries

- Cement

- Chemical

- Petrochemical

- Paper manufacturing / processing

- Plastic manufacturing / processing

- Pharmaceutical

- Textile

- Food processing

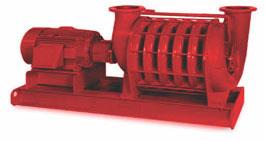

Multistage Centrifugal Blower

Multistage centrifugal Blower consists of a rotating shaft and multi-impellers operating in specially designed Inlet Housing. Outlet Housing and Intermediate Sections. The impellers are accurately balanced. This is a multi-impeller and multi-stage assembly. The number of stages and speed are selected to suit the customer’s exact requirements.

Drives:

They are usually V-Belt driven from electric motors.In the larger sizes the machines can be direct coupled to electric motors.

Mountings:

The mahine and motor can be mounted on base frame fabricated and machined from steel in plain Horizotal in line style or a box type vertical style saving the space.

Tube Axial Fans

|

Industrial Fan

|

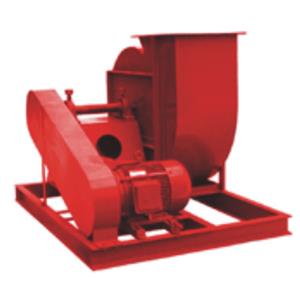

Forced Draught Fan

|

Vane Axial Fan

|

Cross Flow Fans

|

Fume Extractor

|

Cyclonic Dust Collection System

|

Multi Cyclone Dust Collector

|

Dust Extraction Systems

|

Duct Fan

|

Water Cooled Blowers

|

Ventilation Blower

|

Direct Drive Blowers

|

Flange Mounted Blowers

|

Cooling Blowers

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.